Key Takeaways

- 30% reduction in propagation time: AVF+ demonstrated a 9–14 day shorter cycle for young tomato plants compared to conventional greenhouse methods. Julia Erftemeijer noted this improvement reflects growers’ increasing demand for predictability and efficiency during propagation.

- Higher germination and healing success: Success rates improved by up to 16% across germination, grafting, and pinching stages.

- Improved plant quality and uniformity: Julia Erftemeijer emphasized the importance of producing uniform young plants to streamline downstream crop management and ensure high quality.

- Modular, scalable configurations: AVF+ Freestyler, Fusion, and Compact units offer flexibility for varying operation sizes and facility layouts.

- Sustainability considerations: Reduced input material use (12–16%), potential for fewer chemical applications, and enhanced biocontrol integration.

Artechno Presents Its AVF+ Propagation Unit During TomatoTech

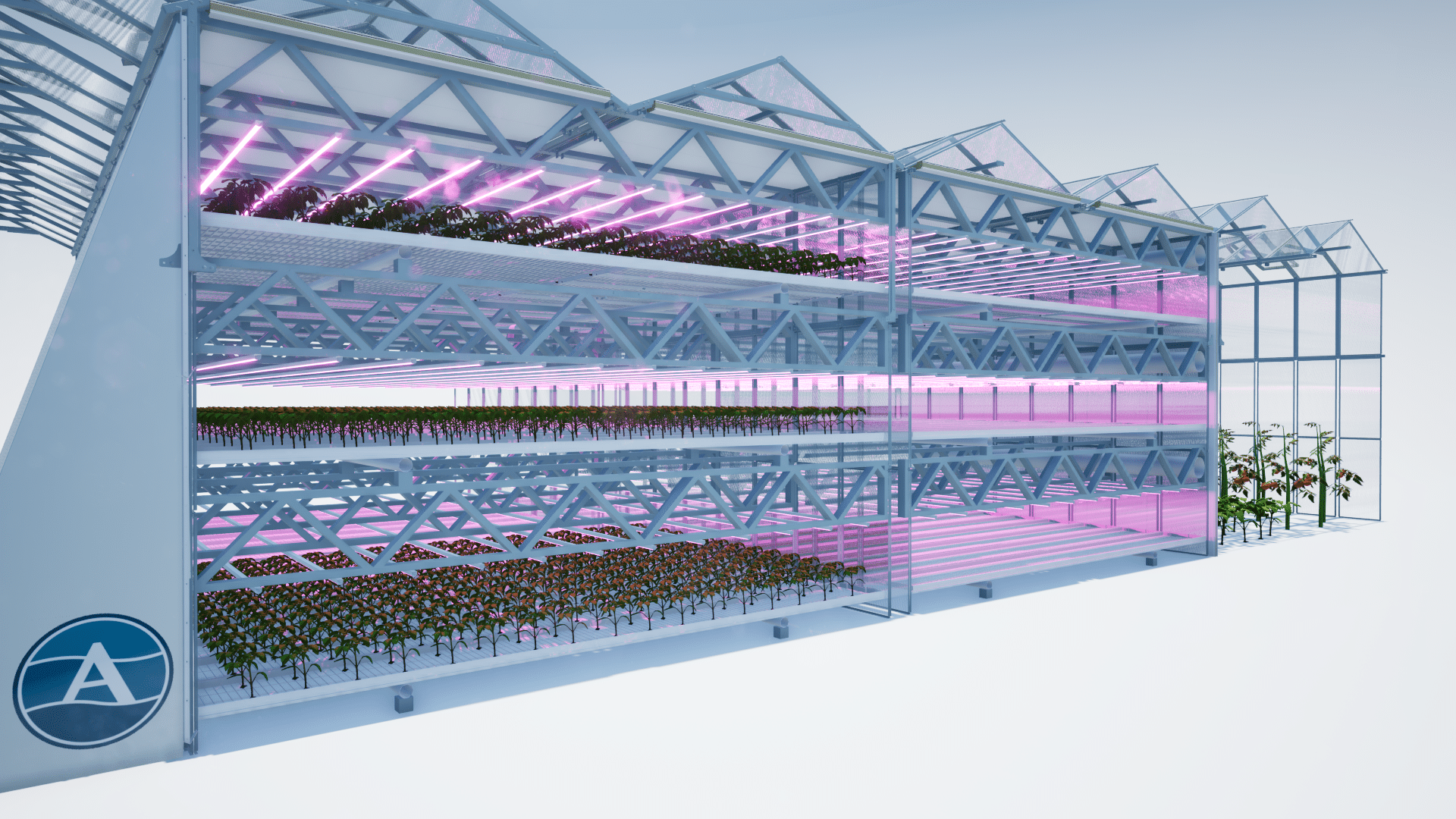

At the TomatoTech Innovation Summit, Artechno Growsystems (Profile) presented new performance data for its AVF+ propagation system, designed to improve young tomato plant production. According to the data, the AVF+ system accelerates propagation timelines and increases overall success rates in germination, graft healing, and pinching phases when compared to traditional greenhouse methods.

“Growers are constantly looking for predictability, quality and higher efficiency during propagation. With AVF+, we’re providing data that shows what is possible when you control the climate, light, airflow, Co2 & irrigation settings,” said Julia Erftemeijer, Sales Consultant Vertical Farming at Artechno.

Measured Results: Faster Propagation and Higher Success Rates

Artechno’s side-by-side analysis compared key performance metrics of greenhouse production and AVF+:

| Phase | Difference |

| Germination + Propagation | 2–6 days faster; 8% higher success rate |

| Healing after Grafting | 3 days faster; 4–8% higher success rate |

| Pre-Pinching Growth | 3 days faster |

| Post-Pinching | 1–2 days faster; improved uniformity |

“Uniformity and plant quality have a direct impact on downstream production. The more consistent your young plants are, the easier it becomes to manage your entire crop cycle,” said Erftemeijer. “With the AVF we can create a controllable plant environment and with that we can achieve two even shoots which is very hard to achieve in greenhouse conditions, yet prevalent to ensure high quality plants later on.”

Artechno’s Modular Solutions for Various Operations

Artechno also presented three AVF+ healing chamber solutions to accommodate operations of different sizes:

- AVF+ Freestyler: Designed for healing grafted plants on a smaller scale (automated climate control – manual logistics (in&outfeed) of the plants)

- AVF+ Fusion: A modular configuration for larger-scale propagation, integrated in the greenhouse construction with current logistical container partner. Automated climate control and logistics of the crops

- AVF+ Compact: Optimized for space-constrained facilities. With automated climate control and logistics

“These systems allow growers to select a configuration that matches their scale and operational goals. Whether you're producing for research or commercial volumes, we aim to offer flexibility and the best system for the best business case,” Erftemeijer explained.

Operational Inputs and Sustainability Considerations

While AVF+ systems were reported to use, Artechno noted reductions in input costs and material use:

| Input Category | Greenhouse | AVF+ | Reported Difference |

| Growing Materials | Baseline | 12–16% less usage | Reduced seed and substrate use |

The system was also presented as enabling:

- Reduction in use of herbicides and pesticides

- Improved integration of biocontrol measures

- Year-round, consistent plant production

- Lower CO₂ impact per viable plant due to reduced losses

Summit Reflections and Future Outlook For Artechno’s AVF+

The TomatoTech Innovation Summit, organized by Artechno Growsystems and TTA ISO, brought together industry professionals to explore advancements in tomato propagation. Artechno used the opportunity to communicate how its AVF+ technology could support growers in meeting their goals for consistency, efficiency, and reduced waste.

“Our goal is to enhance existing production by offering an integrated solution that complements or, where needed, substitutes current methods—delivering predictable outcomes and measurable value.” said Erftemeijer. “Every operation has different needs, and AVF+ is designed to be a tool growers can trust and adapt.”

The AVF+ system, engineered in the Netherlands, continues to be developed with a focus on supporting high-value horticultural crops through controlled-environment agriculture.

Read our latest report on the European Indoor Farming Market here.

Join our network here.