Key Takeaways

- OnePointOne and AutoStore have launched Opollo Farm, an automated vertical farming system in Phoenix.

- The system grows herbs and vegetables in 15 days, about half the time of traditional farming methods.

- Opollo Farm addresses challenges such as labor shortages, water scarcity, and supply chain disruptions.

- The collaboration combines AutoStore’s robotic cube storage with OnePointOne’s precision agriculture technology.

- Fresh produce grown by Opollo Farm is now available at Whole Foods locations in the Phoenix area under the “Willo” brand.

OnePointOne’s Role in Transforming Urban Agriculture

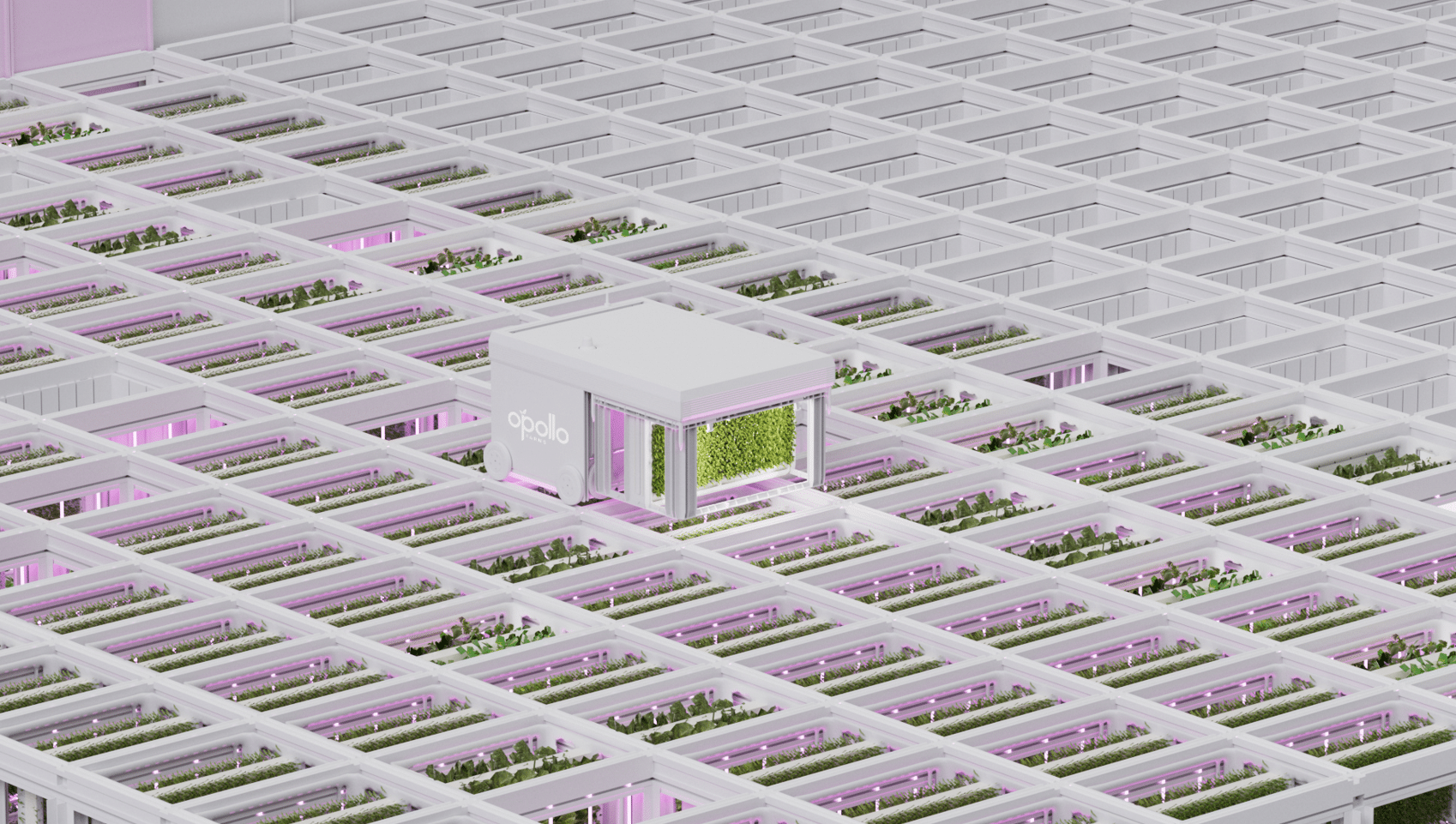

OnePointOne, in partnership with AutoStore, has introduced Opollo Farm, a fully automated vertical farming platform situated just outside Phoenix, Arizona. This new facility integrates robotic technology to optimize plant growth, offering a solution to pressing agricultural challenges such as water scarcity, labor shortages, and the need for local food production.

Plants grown at Opollo Farm move autonomously through a cube storage system that constantly adjusts environmental conditions for optimal results. The system supports high-density cultivation, hydroponics, and a fully controlled environment, enabling year-round harvests of leafy greens and herbs.

“At Whole Foods Market, we’re constantly exploring new ways to bring fresh, sustainable food to our customers,” said Chris Petroulakis, Category Merchant for Produce at Whole Foods Market. “Opollo Farm is a perfect example of how advanced technology can revolutionize local agriculture, helping to deliver high-quality, locally grown produce right to our stores faster and fresher than ever before.”

OnePointOne and AutoStore’s Opollo Farm: Technology and Sustainability in Action

Inside the Opollo Farm System Powered by OnePointOne

At Opollo Farm, plants are seeded automatically and moved through a precision-controlled environment using AutoStore’s cube storage robotics. This automation allows each plant to receive tailored water, nutrient, and light inputs. The farm’s closed-loop hydroponic system reduces water usage by up to 95% compared to traditional farming, while its high-density architecture allows urban placement, significantly shortening the food supply chain.

How OnePointOne Integrates Automation for Scalable Farming

Key features of Opollo Farm include:

- Hydroponic Growing System: Recirculating water systems reduce overall consumption.

- High-Density Cultivation: Maximizes yield per square foot in compact urban spaces.

- Automated Movement: Bins are seamlessly moved by robots to optimize growing conditions.

- Scalability: Modular design allows for easy expansion based on demand.

- Controlled Environment: Protects crops from pests and reduces dependency on pesticides.

- Local Distribution: Urban proximity cuts transportation emissions and supply chain times.

Sam Bertram, CEO of OnePointOne, emphasized the environmental advantages: “With AutoStore’s modular robotics and our plant-production technology, we can grow food almost anywhere using a fraction of the resources traditionally needed.”

Expanding the Future of Vertical Farming

Looking ahead, OnePointOne and AutoStore are exploring opportunities to expand Opollo Farm into more urban locations. While the system is currently in the pilot phase, it is already supplying fresh greens and herbs under the “Willo” brand at select Whole Foods stores in the Phoenix area.

1 Comment