Key Takeaways:

- Rooted Robotics has developed tools for microgreen and baby green production, targeting labor-intensive processes.

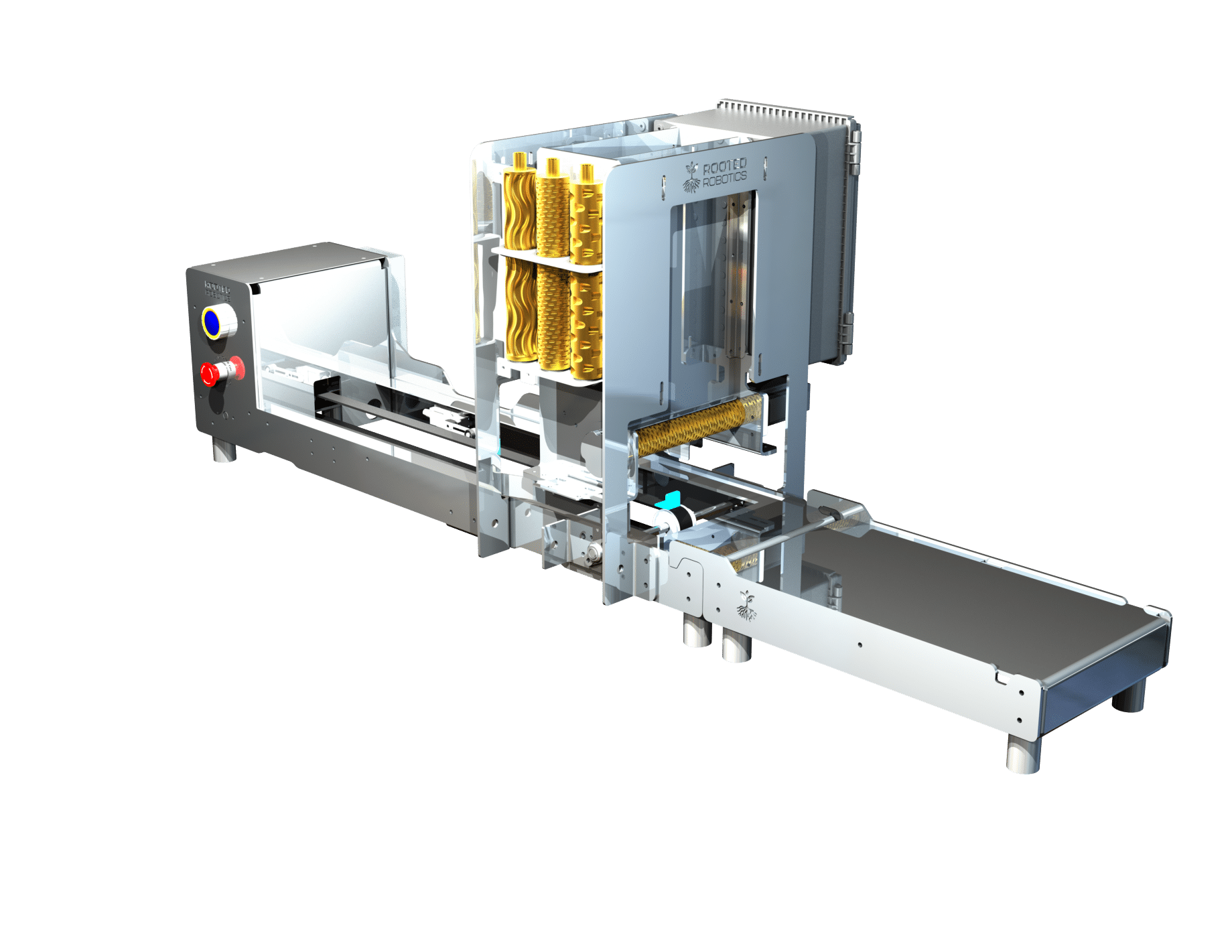

- The Seeder, Washer, and Harvester address market gaps by offering scalable and affordable automation.

- Products are designed based on grower feedback, ensuring versatility and ease of use.

- The company focuses on scalable solutions tailored to small and medium-sized growers while also addressing broader industry challenges.

The controlled environment agriculture (CEA) sector continues to evolve with a growing emphasis on automation to improve efficiency and address labor shortages. Rooted Robotics (Profile) is contributing to this shift by offering practical tools designed for microgreen and baby green production. Eric Roth, Co-Founder and COO of Rooted Robotics, shared insights into the company's strategic approach to product development, its focus on market gaps, and its broader vision for indoor farming.

Filling Automation Gaps

Small and medium-sized CEA growers often face challenges in accessing automation tailored to their needs. According to Roth, the market has lacked affordable solutions for critical tasks such as seeding, harvesting, and cleaning. “We designed our Seeder, Washer, and Harvester to address the most significant inefficiencies growers encounter, such as uniform seed distribution, labor-intensive tray cleaning, and consistent harvesting,” he explained.

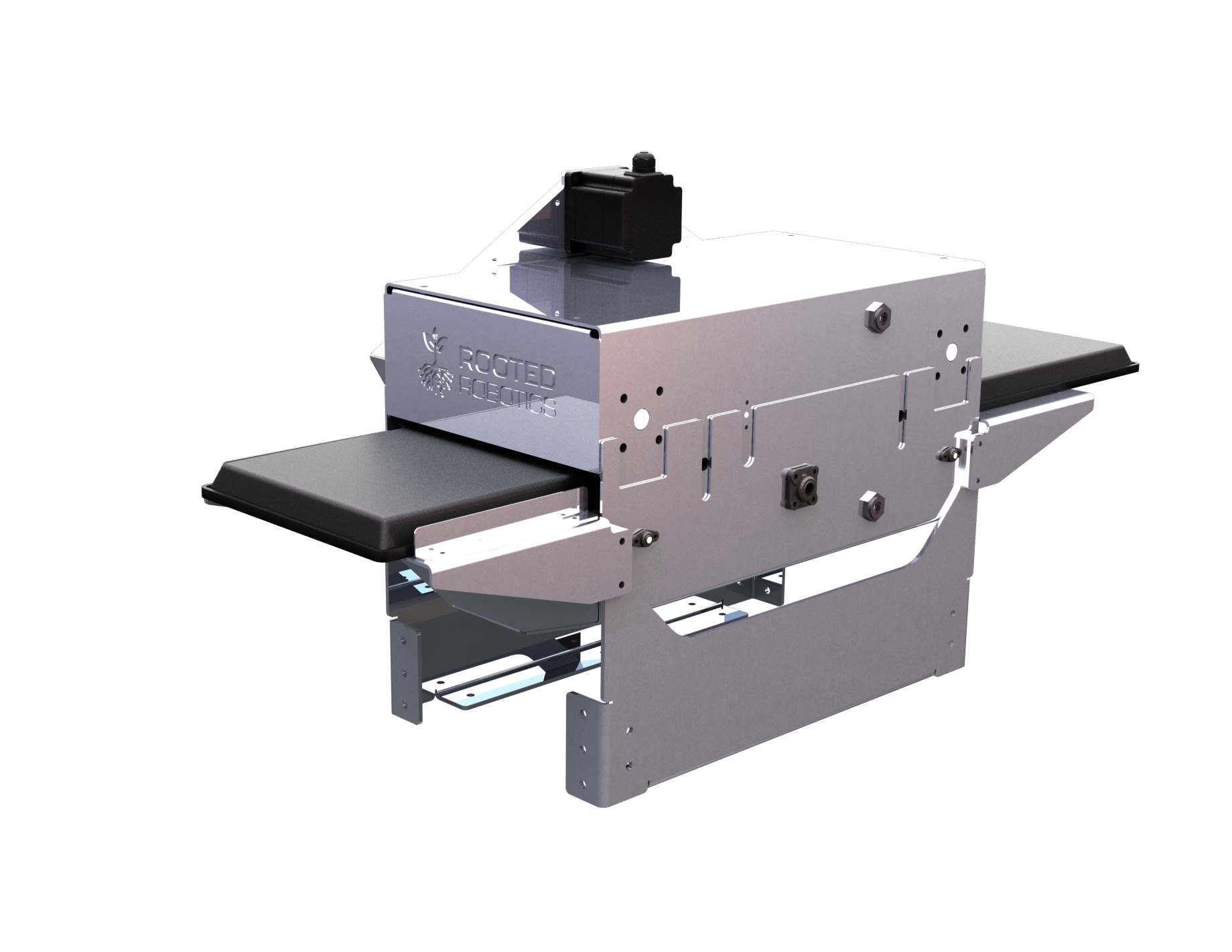

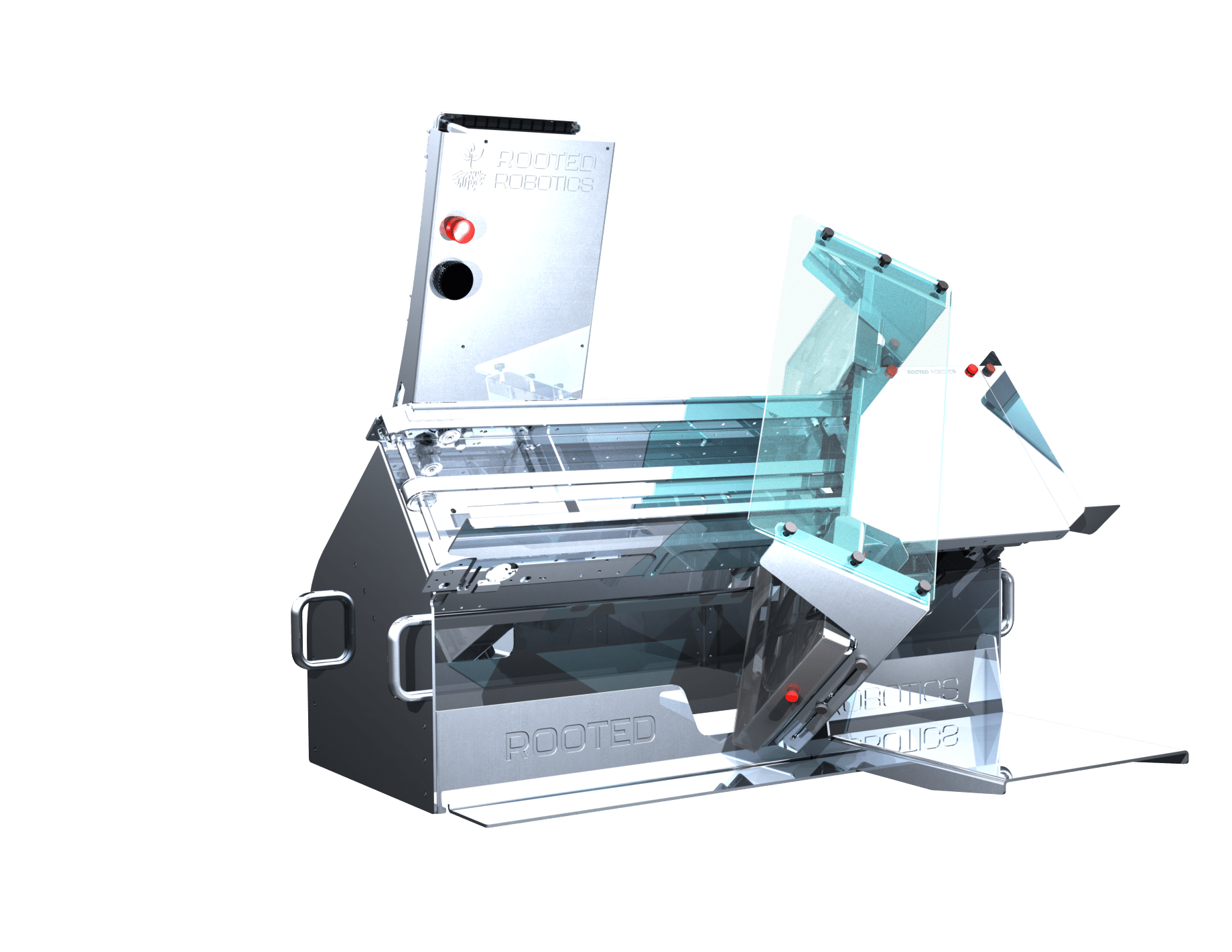

Rooted Robotics' products aim to reduce manual labor while improving consistency:

- Seeder: Distributes seeds uniformly, helping growers achieve consistency and increase yields.

- Washer: Simplifies tray and NFT channel cleaning, saving time and water.

- Harvester: Enables efficient, clean cuts while preserving crop quality.

These products address common pain points, focusing on improving efficiency for smaller-scale operations.

Product Development Based on Feedback

Rooted Robotics integrates feedback from growers quickly to refine its products and ensure they meet operational needs. Roth highlighted upgrades to the Seeder, such as pre and post-seeding watering bars and a vibrational motor coupled with a soft roller for soaked and irregular sized and shaped seed varieties.

“These adjustments were made to accommodate a variety of crop types and ensure that growers could achieve consistent results across different varieties,” Roth noted.

To ensure adaptability, the products are compatible with industry-standard 1020 trays, offering scalability for both small operations and larger farms.

Addressing Industry Challenges

Economic constraints and labor shortages are persistent issues for small and medium-sized CEA growers. Roth emphasized that Rooted Robotics focuses on affordability without compromising functionality. “We aim to strike a balance by offering automation that provides value through essential features, durability, and ease of use,” he stated.

The Seeder, for instance, not only improves efficiency but also minimizes maintenance costs, helping growers maximize return on investment.

Adapting to Market Trends

Rooted Robotics has also worked on custom automation projects for container and vertical farming, reflecting the growing demand for tailored solutions. Roth explained that the company encourages growers to align farm designs with standardized, scalable automation to keep costs manageable.

“The goal is to create solutions that integrate seamlessly into farming operations, reducing the need for costly, bespoke systems,” Roth said.

Future Vision: Scalable and Connected Systems

Rooted Robotics is expanding its focus on modular systems that can grow alongside farm operations. The company’s new Linear Integrated Networked Conveyor (L.I.N.C.) technology aims to automate entire workflows by linking machines together. For the Seeder, they will be building a tray denester, tray filler and top coater. They will also be building the necessary machines to dump the media from the tray post-harvest allowing a seamless connection from the Harvester to the Washer. The goal is to offer affordable automated workflows with minimal human intervention and a fast return on investment.

“This approach will help streamline processes, reduce manual effort, and enhance consistency across operations setting companies up for profitability,” Roth said. The company plans to roll out these integrated systems in the coming year, emphasizing sustainability and scalability.

Exploring New Areas

Rooted Robotics is also exploring automation solutions for other sectors of CEA, including mushroom farming, fruiting crops, and nurseries. While still in the early stages, the company is examining how its approach to modular automation can address challenges in these markets.