Key Takeaways

- Smart Monitoring and Controls reduced supplemental lighting energy use by 53–78% in modeled scenarios.

- Variable-frequency drive ventilation controls cut electricity use for fans by an average of 63%.

- Field demonstrations were conducted across multiple California climate zones and crop types.

- ERI recommends utility rebate programs to improve automation project payback periods.

- Participating growers continue expanding wireless monitoring and automation systems for ongoing optimization.

Pilots with Commercial Growers Uncover Savings from Smart Monitoring And Controls

A new report outlines how Smart Monitoring and Controls technologies can substantially reduce energy use in controlled environment agriculture (CEA) facilities. Funded by electric utilities in California and completed in 2025 by Energy Resources Integration (ERI) in partnership with Microclimates Inc., the study examined integrated automation systems for greenhouses and indoor farms.

The study explored energy efficiency opportunities for California’s CEA floriculture, food, cannabis, and fungi markets. The report found that Smart Monitoring and Controls systems—including climate and energy sensors along with the controllers and software that automate HVAC, lighting, and irrigation equipment—can save electricity and reduce operating costs for greenhouse growers and indoor farmers.

Field Demonstrations Across Climate Zones

ERI researchers validated the energy-saving potential of Daily Light Integral (DLI) controls for greenhouse lighting and variable-speed fans for greenhouse ventilation using data gathered from four field demonstrations at commercial greenhouses and indoor farms in California.

Field tests conducted in facilities in different climate zones demonstrated the significant savings potential of Smart Monitoring and Controls. Growers integrated new sensors with Microclimates software to visualize environmental trends across zones of control.

ERI researchers used data from the California field demonstrations to create energy models for energy-saving control strategies. Energy models estimate that automated greenhouse Daily Light Integral (DLI) controls can reduce electricity use from supplemental lighting systems by 53 to 78 percent for tomatoes, leafy greens, and cannabis crops. Meanwhile, variable-frequency drive (VFD) controls for greenhouse ventilation fans can reduce electricity use for ventilation by an average of 63 percent.

Grower Feedback on Data-Driven Optimization

Based on these compelling results, the research team recommended that California’s electric utilities should create new rebate programs for automated lighting and ventilation controls to help improve the payback period of Smart Monitoring and Controls projects. Gretchen Schimelpfenig, ERI’s emerging technologies program manager and researcher, shared that the research “demonstrated measurable energy savings potential and provided the foundation for future utility program design. We hope that new rebates for automation strategies will launch soon to boost the benefits of automation hardware and software investments for California growers.”

One of the commercial grower study participants continues to adopt wireless monitoring and automation systems at their greenhouse operation, using Microclimates for climate computing. “For a long time, I was looking for remote sensors to add to the climate computer so I can compare our measured results with the actions we take with heat pipes or screen positions. Working with remote sensors gives more insight into air movement and temperature differences in a greenhouse at each level (under benches, crop level, under the energy screens, and above the energy screens),” shared Edwin Knijnenburg, Orchid Growing Specialist at Floricultura Pacific.

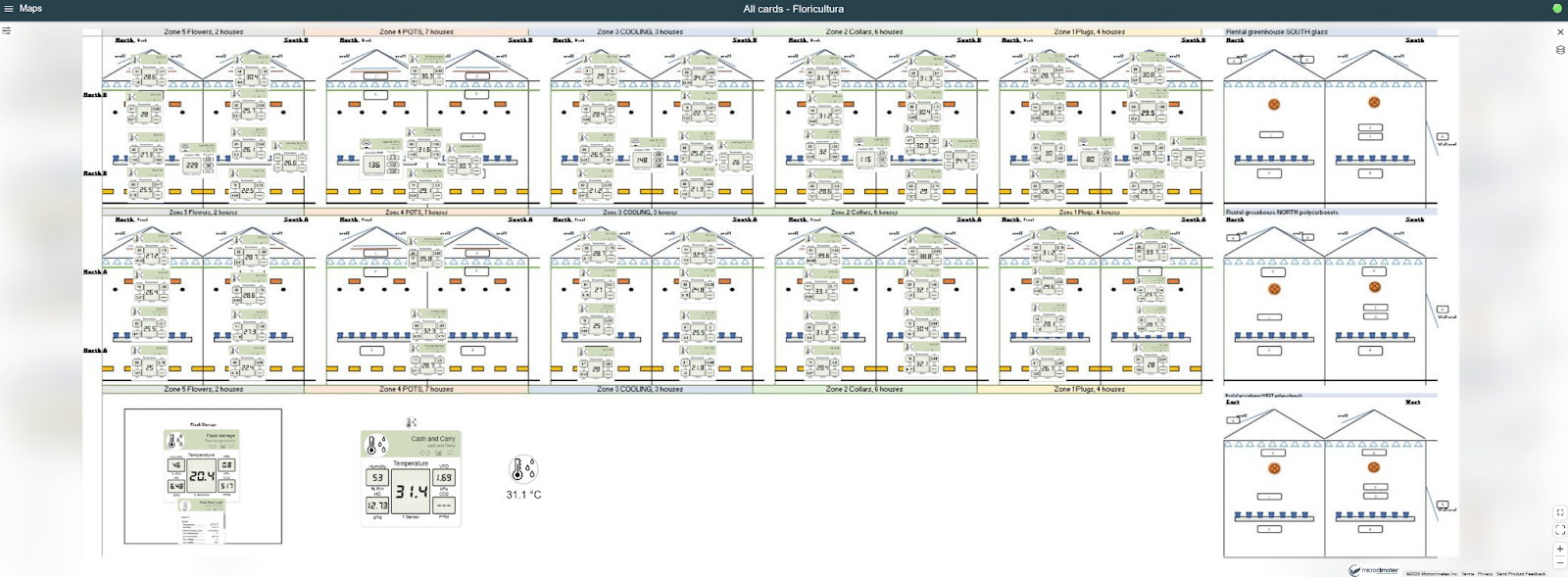

Floricultura has expanded their Microclimates dashboard to include a detailed map of each greenhouse’s key climate parameters. Edwin finds data visualization to prove which strategies work: “It gives you tools to investigate further. I am especially focused on screen positions and gap strategies. How big of a gap do I need for the most evaporation without losing too much heat by opening the screen too far?”

Neda Vaseghi, CEO of Microclimates, highlights how automation can be a continuous improvement opportunity for many existing operations in 2026. “When you combine years of hands-on experience with good data, you start to see where real changes can be made without relying on assumptions. Having better visibility into how the environment behaves in real-time guides informed adjustments. As Floricultura continues to build on this approach, it’s clear that optimization isn’t a one-time project—it’s an ongoing process.”