Key Takeaways

- Pow.Bio has opened a 25,000 sq. ft. biomanufacturing facility in Alameda, California, designed to advance AI-enabled continuous fermentation.

- The facility offers increased scale-up capacity, enabling seamless transitions from lab-scale testing to large-scale ingredient production.

- Pow.Bio’s proprietary AI-driven fermentation platform allows for rapid process development and predictive control, reducing variability and improving efficiency.

- The site includes FDA-registered, food-grade production capabilities and advanced downstream processing (DSP) options, such as spray drying and lyophilization.

- Pow.Bio’s fermentation technology can be integrated into existing manufacturing facilities worldwide across food, agriculture, chemicals, materials, and medicine.

Pow.Bio Expands Biomanufacturing with New Alameda Facility

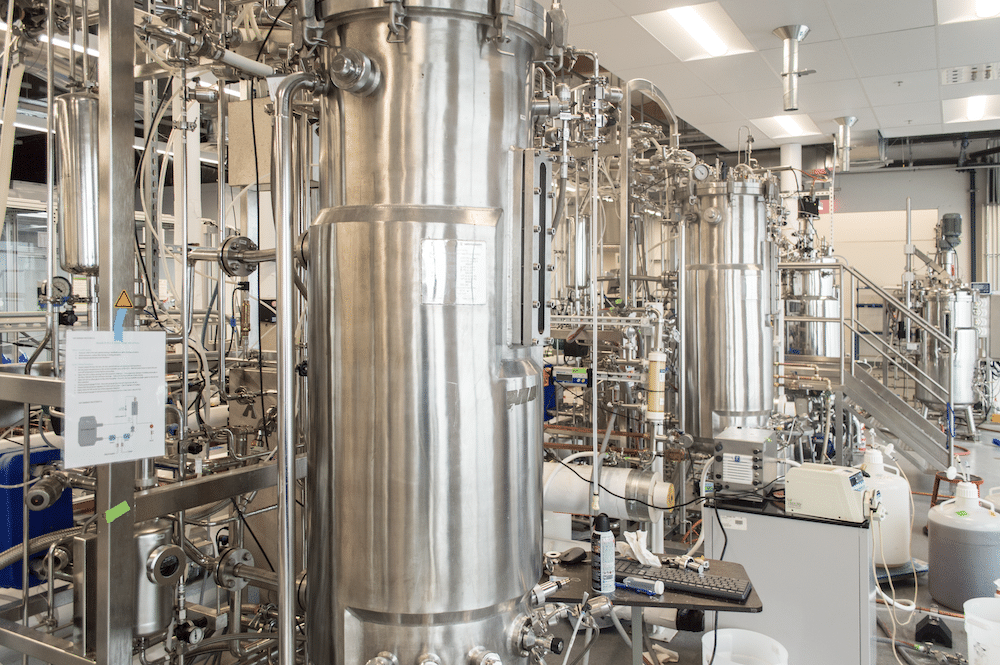

Pow.Bio, a leader in innovative biomanufacturing solutions, has announced the opening of its new 25,000 sq. ft. facility in Alameda, California. Located at Marina Village, the state-of-the-art production site is equipped with AI-driven continuous fermentation systems, designed to help partners achieve target production costs while maintaining high efficiency and scalability.

“Today, many promising bio-products are challenged with high production costs and prolonged development timelines,” said Shannon Hall, CEO of Pow.Bio. “The new Alameda facility is an active, working demonstration site for Pow.Bio’s modern, cost-effective manufacturing solution that is delivering meaningful gains for our partners right now.”

The new facility serves as a real-world demonstration site, showcasing Pow.Bio’s AI-enabled fermentation technology and its ability to accelerate product development across multiple industries.

Pow.Bio’s AI-Enabled Continuous Fermentation Technology

The Alameda facility features several key advancements in biomanufacturing, including:

- AI-Enabled Continuous Fermentation: Pow.Bio’s proprietary dual-chamber fermentation system provides greater process stability, improved yields, and cost-effective production.

- Increased Scale-Up Capacity: The facility allows for seamless transition from small-scale testing to large-scale ingredient production, supporting hundreds of kilograms of output.

- Advanced AI-Driven Fermentation Software: Proprietary predictive control technology ensures autonomous fermentation, reducing process variability and improving efficiency.

- Food-Grade Production: The FDA-registered cleanroom meets the highest standards for food and beverage applications, providing pilot-scale fermentation and downstream processing.

- Expanded Downstream Processing (DSP): The site includes spray drying and lyophilization, supporting a wide range of product finishing needs.

“Our advanced demonstration facility is setting a new standard for the industry,” Hall added. “Our AI-driven production platform is delivering results that bring the most exciting products to market faster.”

Pow.Bio’s Technology Offers Scalable Biomanufacturing Solutions

The new Alameda facility is designed as a scalable model for the deployment of intelligent fermentation systems. Pow.Bio’s technology can be integrated into existing biomanufacturing facilities worldwide, offering flexible solutions across multiple industries, including:

- Food and agriculture – sustainable ingredient production and fermentation-based food processing.

- Materials and chemicals – bio-based alternatives for industrial applications.

- Pharmaceuticals and medicine – precision biomanufacturing for biotech innovations.